INFORMATION FOR EVERY BUFFING WHEEL OPERATOR

WARNING: Your Safety Depends On Carefully Following These Guidelines.

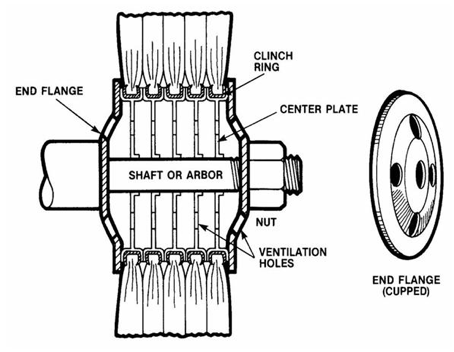

1. Arbor hole size and shaft size must match. For example, if you’re using a 1” diameter shaft your buffing

wheels MUST have a 1” diameter arbor hole.

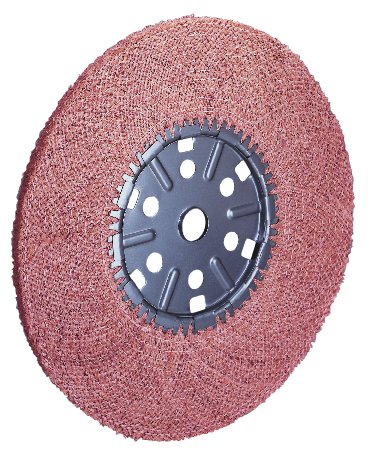

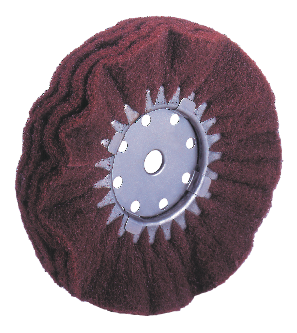

2. End flanges must securely clamp the buffs. Make certain they’re sized properly and exert enough pressureto secure the buffs.

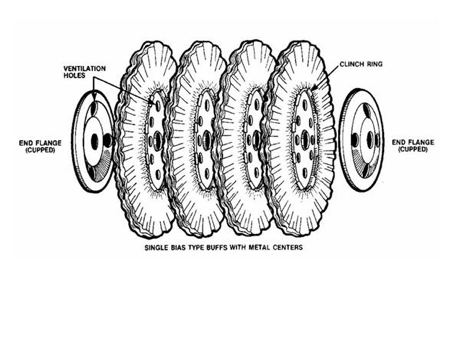

3. Flanges MUST be installed with concave side toward buffs, and be large enough to cover the outer tips of the metal clinch ring teeth. The correct flanges are cupped. Flanges 4-1/2” in diameter and larger have ventilating holes in the cupped area.

4. Arbor shaft threads must be in good condition, and long enough to allow the nut to be tightened for firm

clamping of the buff and end flanges.

5. Shaft nuts must be firmly tightened with a wrench.

6. Shaft nuts must be periodically checked for tightness and re-tightened as necessary.

7. Follow these rules when using spacers between buff sections:

- Spacers must be large enough to cover outside tips of clinch ring teeth, just like end flanges.

- When spacers are used to support buff centers, they MUST be of proper diameter to support the

entire clinch ring inside diameter. - Flange areas of the spacers MUST securely clamp the buff. Make certain that the buff support and

interlock areas do not prevent proper flange pressure on the buff. - THE BUFF RING MUST NOT SPIN ON THE SPACER OR HUB. This will break the clinch ring

and/or burn the buff.

8. NEVER exceed the maximum RPM ratings given in the chart below.

9. Check the machine manufacture’s guarding recommendations, and make certain they are followed.

10. Small and irregular parts should be buffed only while in proper holding fixtures or similar devices.

11. Avoid loose fitting clothes and NEVER reach over a rotating buff or fixture.

12. Don’t leave running machines unattended.

13. Read and observe all safety recommendations of the buffing machine manufacture, compound supplier, and your own safety department. Pay particular attention to rules concerning eye protection, hair, and hands such as wearing safety glasses, gloves, hairnets, aprons, respirators, etc.

THESE RULES ARE MADE FOR YOUR PROTECTION. BE SAFE. FOLLOW THEM.

NEVER USE AN END FLANGE SMALLER THAN THE CLINCH RING

Here are the proper diameters for safe operation:

| FLANGE DIAMETER | CLINCH RING DIAMETER |

| 2-3/4″ Inch | 1-1/2″ Inch |

| 4-1/2″ Inch | 3″ Inch |

| 6-1/2″ Inch | 5″ Inch |

| 8-1/2″ Inch | 7″ Inch |

| 10-1/2″ Inch | 9″ Inch |

MAXIMUM SAFE RPM FOR BUFFS PROPERLY CLAMPED WITH RECOMMENDED END FLANGES

CLINCH RING CENTER SIZE

| BUFF DIAMETER | 3″ Inch | 5″ Inch | 7″ Inch | 9″ Inch |

| 6″ – 8″ | 3600 RPM | |||

| 9″ – 10″ | 3450 RPM | |||

| 11″ – 12″ | 3000 RPM | 3450 RPM | ||

| 13″ – 15″ | * | 2700 RPM | 3000 RPM | |

| 16″ – 18″ | * | 1800 RPM | 2400 RPM | 2400 RPM |

| 19″ – 20″ | 1200 RPM | 2000 RPM | 2000 RPM | |

| 21″ – 24″ | * | 1500 RPM | 1800 RPM |

- Available only in special designs intended specifically for low RPM use.