NON-FERROUS BAR COMPOUNDS ARE SOMETIMES REFERRED TO AS WHITE OR BLACK DIAMOND BUFFING COMPOUND.

Intended for buffing non-ferrous metals where the work surface is in good condition, free of deep tool or die marks.

When heavy marks are present, Tripoli Buffing Compound is generally used to first cut down the surface and then a second buffing operation is performed using a “Coloring” Compound to produce a mirror-bright finish.

| PRODUCT NO. | GRADE | DESCRIPTION | |||

| 515-6130 | D-13 |

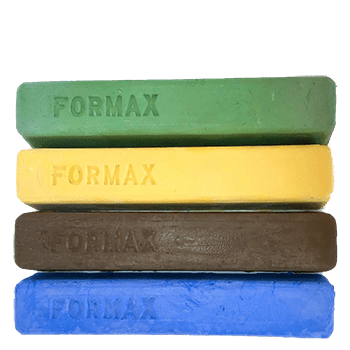

BLACK COLORING COMPOUND (GREASY). This is a greasy, fast cutting grade recommended for tough jobs such as copper plate, nickel plate, plumbing fixtures, furniture tubing, stove parts. Used extensively on automatic buffing machine applications. (Bar color: Black) |

|||

| 515-6131 | D-16 | COLORING COMPOUND (DRY) A very hard, dry grade for light coloring work on zinc die castings, brass and sheet aluminum. Produces a high, lustrous color and being a dry grade, it does not load up on the buff or pack into crevices or recesses of the work. (Bar color: Tan) | |||

| 515-6132 | D-20 | CUT AND COLOR COMPOUND (MEDIUM DRY). A medium dry grade of a light brown color, resulting from the fact that Tripoli abrasive powder has been blended into the formula to increase the cutting action over that normally produced by a White Coloring Compound. The double-duty action resulting from this combination makes it a very popular grade for general all-around job shop work, on non-ferrous metals.(Bar color: Brown) | |||

| 515-6133 | D-35 | COLORING COMPOUND (MEDIUM GREASY) Our most popular grade because it is adaptable for cutting down and coloring the average run of aluminum, brass, and die cast metals. Also used extensively for buffing copper plated articles, particularly where a regular Tripoli Compound is too severe and removes too much of the copper-plate. Contains a sufficient amount of grease binders to be used on most automatic buffing applications. (Bar color: Tan) | |||

| 515-6134 | D-38 | HIGH COLOR COMPOUND (EXTRA DRY) An extra dry grade developed for “coloring out” operations on brass and sheet aluminum. Its light cutting action minimizes the danger of cutting too aggressively on the metal. Also recommended on recessed or indented surfaces that ordinarily would pack up with a greasier grade, giving difficult cleaning problems. Leaves a clear bright finish, free of dirt. (Bar color: Tan) | |||

Packing Information

All grades made in standard 2” x 2” x 10” bar size. Also available in extra long lengths and special shapes to fit buffing compound applicators. Request a Quote for more information.

All grades packed 24 Bars per Carton.