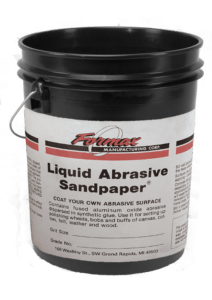

IN LOOSE DRY FORM

A premium- quality fused aluminum oxide abrasive for general industrial purposes. Used for setting up polishing wheels, lapping, blasting and barrel tumbling.

Whatever the abrasive application, it can be considered as a means of changing the work surface to different size, shape, finish, or light reflective surface. Each abrasive particle may be visualized as an individual cutting tool, whether it has singular or multiple cutting edges. As the particle is moved across the work surface an abrading action takes place.

The intensity of the abrading action is dependent, to a large extent, by such characteristics as: (1) hardness, (2) toughness, (3) particle size, shape, and uniformity, (4) fracture resistance, (5) wettability (with other materials with which it will be employed).

Aluminum Oxide is a manufactured abrasive that can be controlled for hardness, particle size, structural shape, toughness and fracturability.

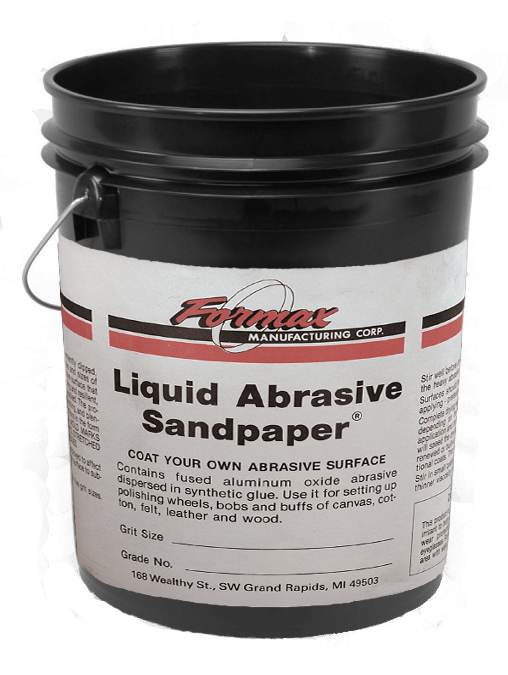

GRIT SIZE AND PRODUCT NUMBER

| CONTAINER SIZE | 80 COURSE | 120 MEDIUM | 180 MED. FINE | 240 FINE | 320 EXTRA FINE |

| 5-Gallon Plastic Pail | 515-6208 | 515-6209 | 515-6210 | 515-6211 | 515-6212 |

Aluminum oxide starts out in the form of bauxite ore, which is a clay-like aluminum hydroxide. The bauxite is calcined, (this drives off the water), mixed with iron particles and ground coke and then placed in an electric arc type furnace.

Within the furnace, the temperature is increased upward to 3500 degrees F. during which time the coke reduces the impurities that, in turn, combined with the iron and precipitate to the bottom of the furnace. Aluminum Oxide is the remaining fused end-product.

After cooling, the process of breaking it down into standard particle sizes begins. This is an involved process requiring crushing, grading, screening, and chemical treatment.

The finished product is a hard and tough crystal with great impact and shock resistant strength. It is ideally suited for abrading high tensile strength metals, such as carbon steels, alloy steels, and tough iron and non-ferrous alloys.