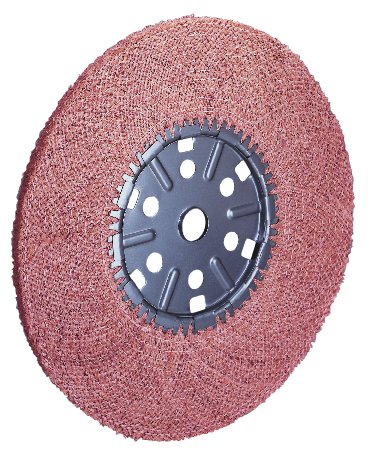

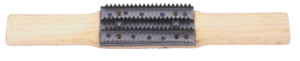

Intended for those buffing operations that require a more aggressive cutting and leveling action than can be obtained with bias cotton buffs.

Type “RS” open-face sisal/cloth buffs effectively remove or blend metal stretcher strains, ripples, score marks, light die and tool marks, and other surface imperfections from drawn, stamped, roll-formed ferrous metals as well as non-ferrous metals. Flexibility is retained, allowing this buff to be particularly adaptable to buffing concave, contoured, recessed and drawn profile forms.

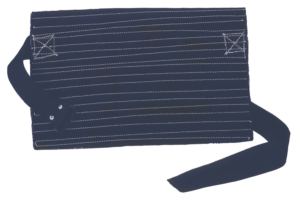

Bias-Cut woven sisal fiber is sandwiched between layers of bias-cut cotton and sewed into a packet strip.

It has unique versatility for buffing both ferrous and non-ferrous metals, including Automotive Parts, Toaster Bodies, Cutlery, Pots and Pans, Steel Stampings, Roll-Formed and Drawn Articles of Carbon and Stainless Steels, Extruded Moldings, Die Castings and more.

12 PLY BIAS CONSTRUCTION, METAL CENTERS, 1/2″ CIRCLE SEWED

| STYLE RS-312 | ||

| PRODUCT NO. | BUFF DIA. | HUB |

| 515-238 | 8″ | 3″ |

| 515-239 | 10″ | 3″ |

| STYLE RS-512 | ||

| PRODUCT NO. | BUFF DIA. | HUB |

| 515-240 | 12″ | 5″ |

| 515-241 | 14″ | 5″ |

| STYLE RS-712 | ||

| PRODUCT NO. | BUFF DIA. | HUB |

| 515-244 | 16″ | 7″ |

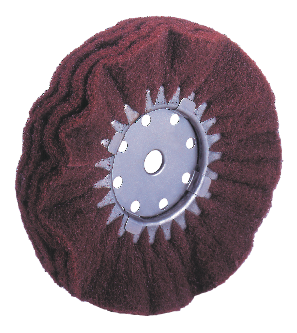

Sisal buffs effectively remove or blend stretcher strains, orange peel, polishing wheel grit lines, abrasive belt lines, light die marks and other surface imperfections from drawn, stamped and roll-formed metals. Surface imperfections left from machine tool marks or grinding wheel grit lines on forged parts can be removed with the use of hard treated sisal buffs.

Sisal buffs are extensively used for finishing steel stampings that require subsequent semi-bright or bright plating. The final finish is enhanced by first sisalizing the base steel to a bright luster. Moreover, the need for “color buffing” the copper or nickel plating may be entirely eliminated.

The finishing of roll-formed, stamped or drawn stainless steel and aluminum articles that are normally first “polished” and then “buffed” may yield to being “sisalized” and thus result in worthwhile savings of time, material and labor.

In other instances, multiple wheel automatic buffing machine operations can be improved simply by installing a buff head or two of sisal buffs in front of the cloth buffs. The objective here is to increase the rate of cut; improve the finish; reduce the timecycle and the number of cloth buffing wheel heads normally required to do the job.