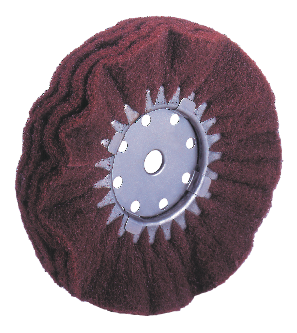

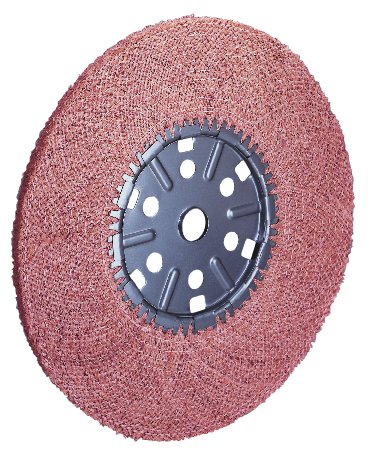

A buffing wheel constructed of sisal will provide both polishing and buffing action.

For example, it is not unusual to reduce or completely eliminate the need for fine grit, set-up polishing wheel operations with the combined polishing and buffing action of sisal buffs.

Sisal is a slender, hard cellular strand of fiber that has demonstrated its great strength and tough resiliency in the form of binder twine, cord and rope for many years. These same qualities, along with its natural abrading and grease absorbing characteristics, provide an ideal buffing wheel fabric.

Sisal buffs are available in a wide variety of constructions. There are a many applications where they can be used to produce a more aggressive buffing action and therefore deserve investigation on your particular buffing operations.

Treatment: Resin dip treatment is recommended when the buffing job requires a stiffer buff with a more aggressive polishing action than untreated buffs can provide. Treating also contributes to longer buff life.

SPIRAL SEWED FLAT FACE TYPE, 8 PLY, 1/2” FACE WIDTH, 3/8” SPIRAL SEWED – RESIN DIP TREATMENT

When ordering, specify: Product Number, Diameter, and Arbor Hole size

| STYLE BS-381 | ||

| PRODUCT NO. | BUFF DIA. | HUB |

| 515-311 | 8″ | 3″ |

| 515-312 | 10″ | 3″ |

| STYLE BS-581 | ||

| PRODUCT NO. | BUFF DIA. | HUB |

| 515-313 | 12″ | 5″ |

| 515-314 | 14″ | 5″ |

| STYLE BS-781 | ||

| PRODUCT NO. | BUFF DIA. | HUB |

| 515-317 | 16″ | 7″ |

Sisal buffs effectively remove or blend stretcher strains, orange peel, polishing wheel grit lines, abrasive belt lines, light die marks and other surface imperfections from drawn, stamped and roll-formed metals. Surface imperfections left from machine tool marks or grinding wheel grit lines on forged parts can be removed with the use of hard treated sisal buffs.

Sisal buffs are extensively used for finishing steel stampings that require subsequent semi-bright or bright plating. The final finish is enhanced by first sisalizing the base steel to a bright luster. Moreover, the need for “color buffing” the copper or nickel plating may be entirely eliminated.

The finishing of roll-formed, stamped or drawn stainless steel and aluminum articles that are normally first “polished” and then “buffed” may yield to being “sisalized” and thus result in worthwhile savings of time, material and labor.

In other instances, multiple wheel automatic buffing machine operations can be improved simply by installing a buff head or two of sisal buffs in front of the cloth buffs. The objective here is to increase the rate of cut; improve the finish; reduce the timecycle and the number of cloth buffing wheel heads normally required to do the job.

More Sisal Buffs

ZIPPO™ BIAS CUT

SISAL

BARS

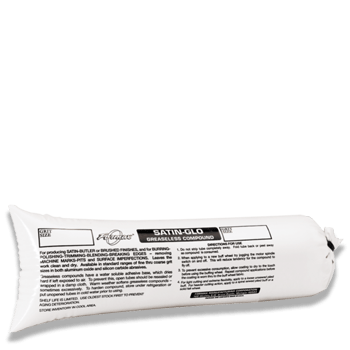

BAR COMPOUNDS

Individually boxed & labeled

GREASE STICKS

How can we help YOU today?

Whether you need a quote, more product information or to locate a distributor, we’re here to answer your questions.

Please contact us!

CONTACT US

How can we help YOU today?

Whether you need a quote, more product information or to locate a distributor, we’re here to answer your questions.

Please contact us!

Call (800) 242-2833

Fax (616) 456-7507

We are located at:

168 Wealthy Street SW,

Grand Rapids MI 49503